What Happens When Product is in Short Supply

A combination of low interest rates, pent-up post-COVID demand, growing millennial families, and a push to the suburbs and exurbs is fueling sustained momentum for the residential housing market.

According to the June 2021 New Residential Construction Report, housing starts were up 6.3% in June 2021 from May, and a robust 29.1% from a year ago.

Can supply keep up? The growing rate of materials shortages and limited skilled labor resources are causing delays and significantly adding to the cost of a new home. High lumber costs throughout the year due to shortages has increased the average cost of a new home by more than $30,000.

While lumber prices have recently come down, material shortages remain a significant issue. Consumer frustration may be creeping in. Housing permits, an early indicator of activity, were down 5.1% in June '21 from May.

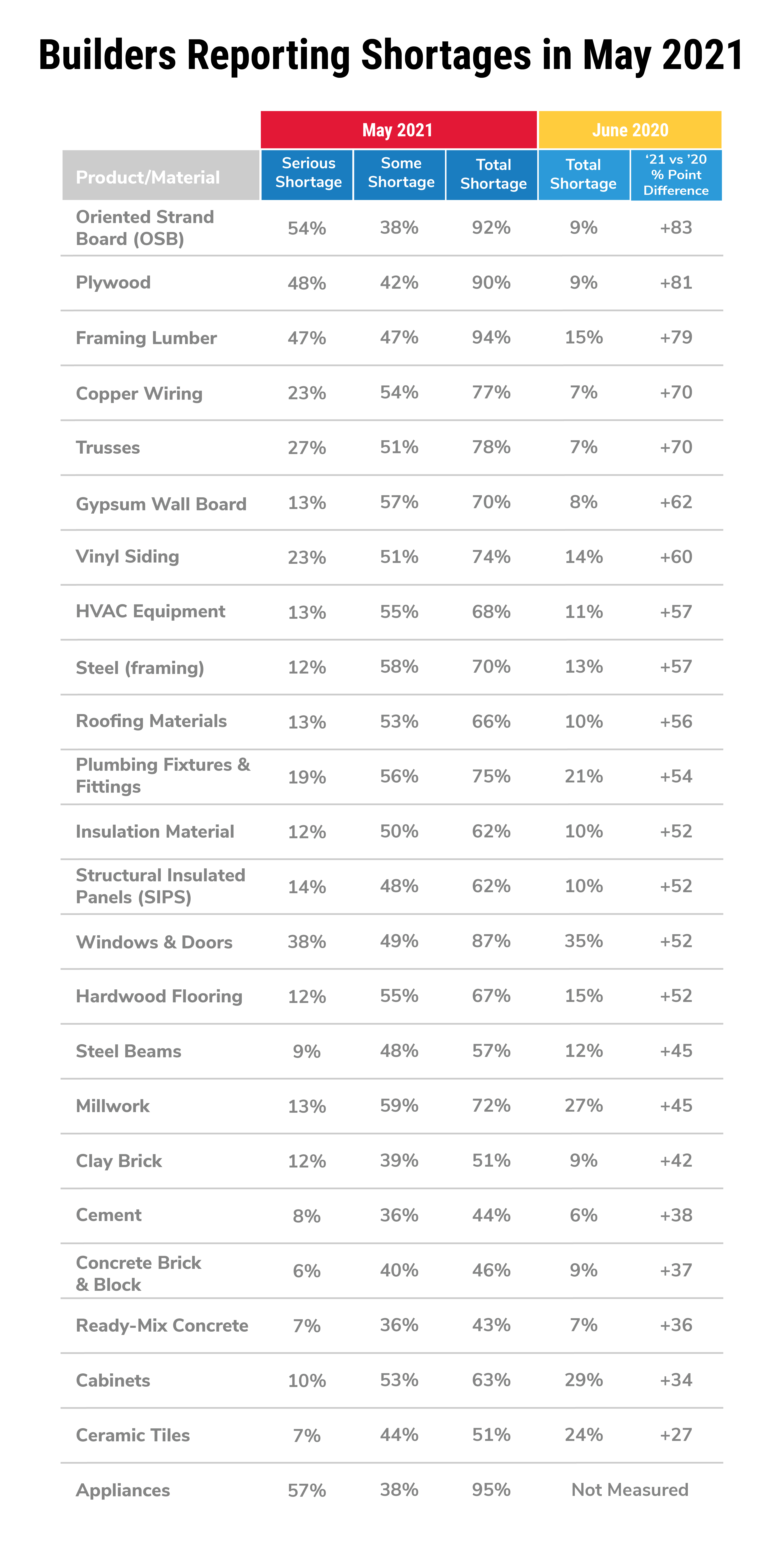

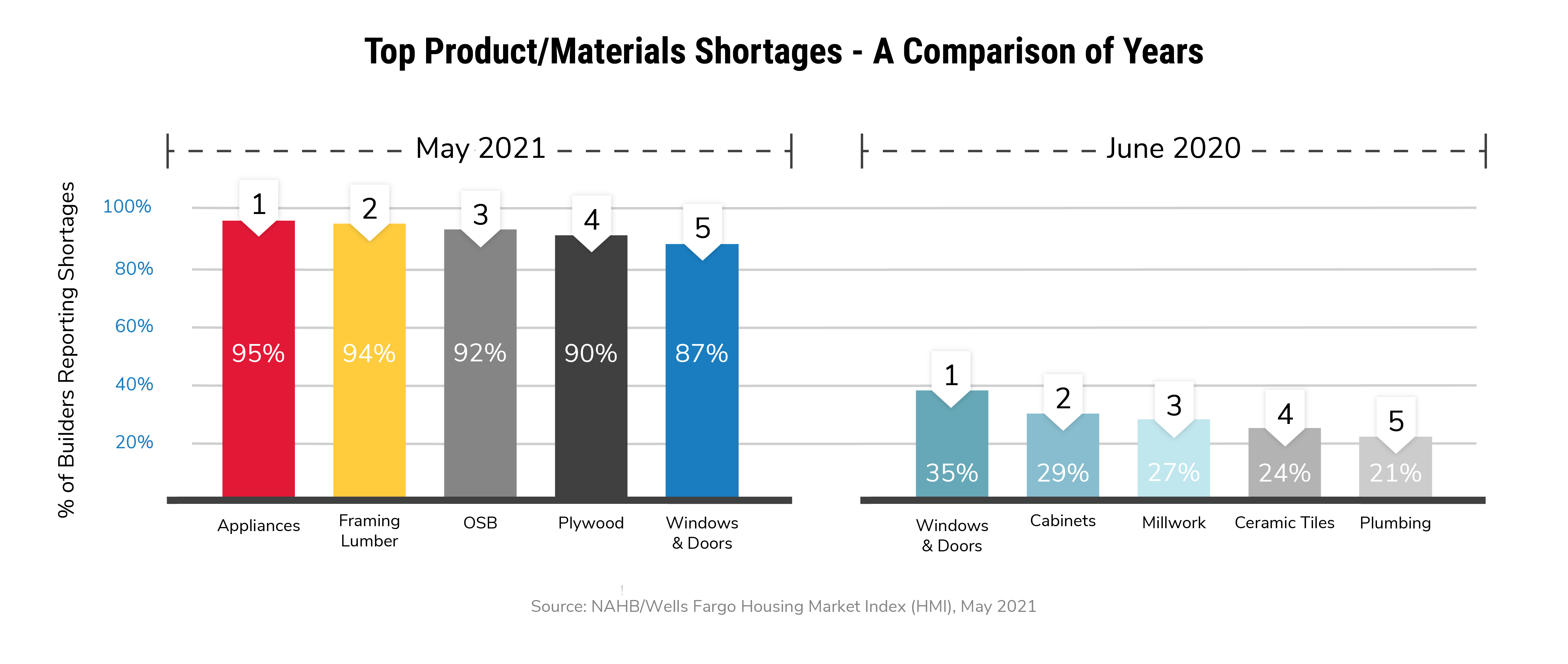

A year ago, the shortages began to affect building materials needed for both remodeling and new construction. As homeowners spent more time at home, they saw more flaws in their homes that they decided to address. Builders began to report on shortages with materials such as windows, doors, cabinets, millwork, tiling, and plumbing. A year later, windows and doors have grown significantly as a shortage concern with the demand pressures being felt both in new construction and remodeling.

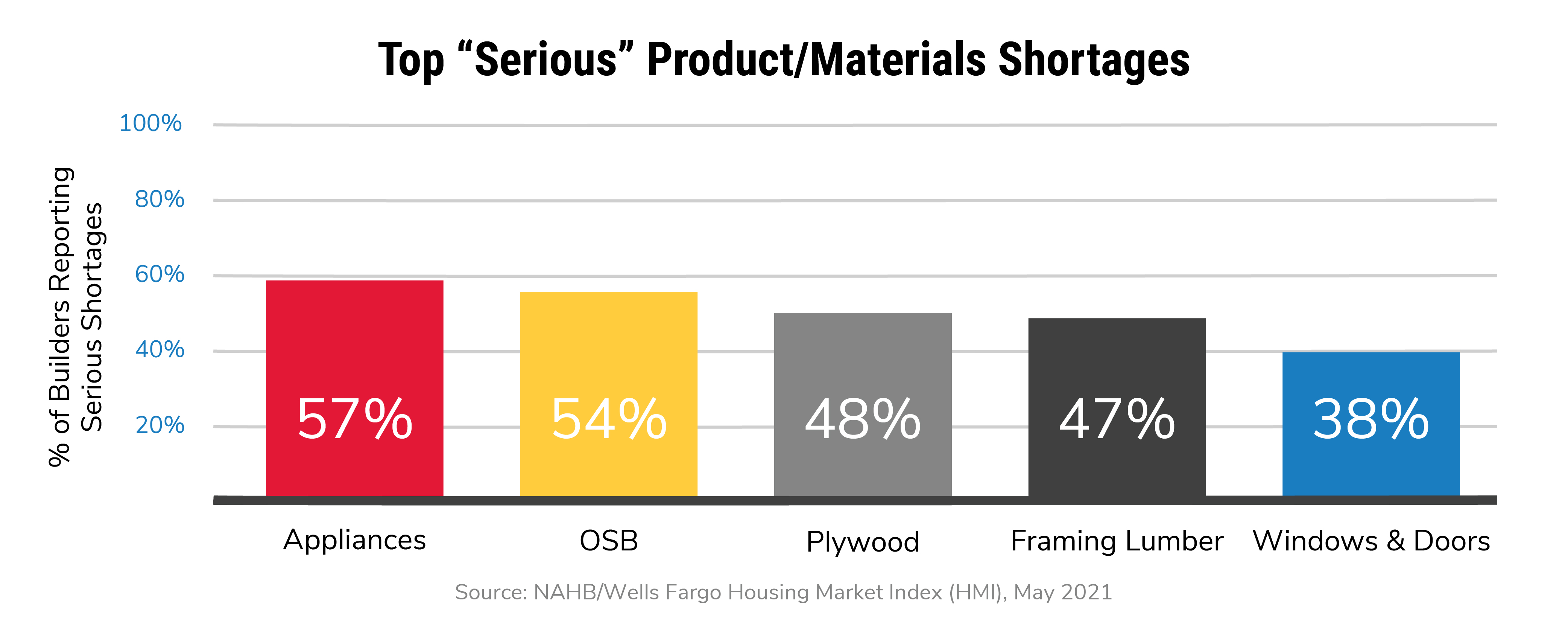

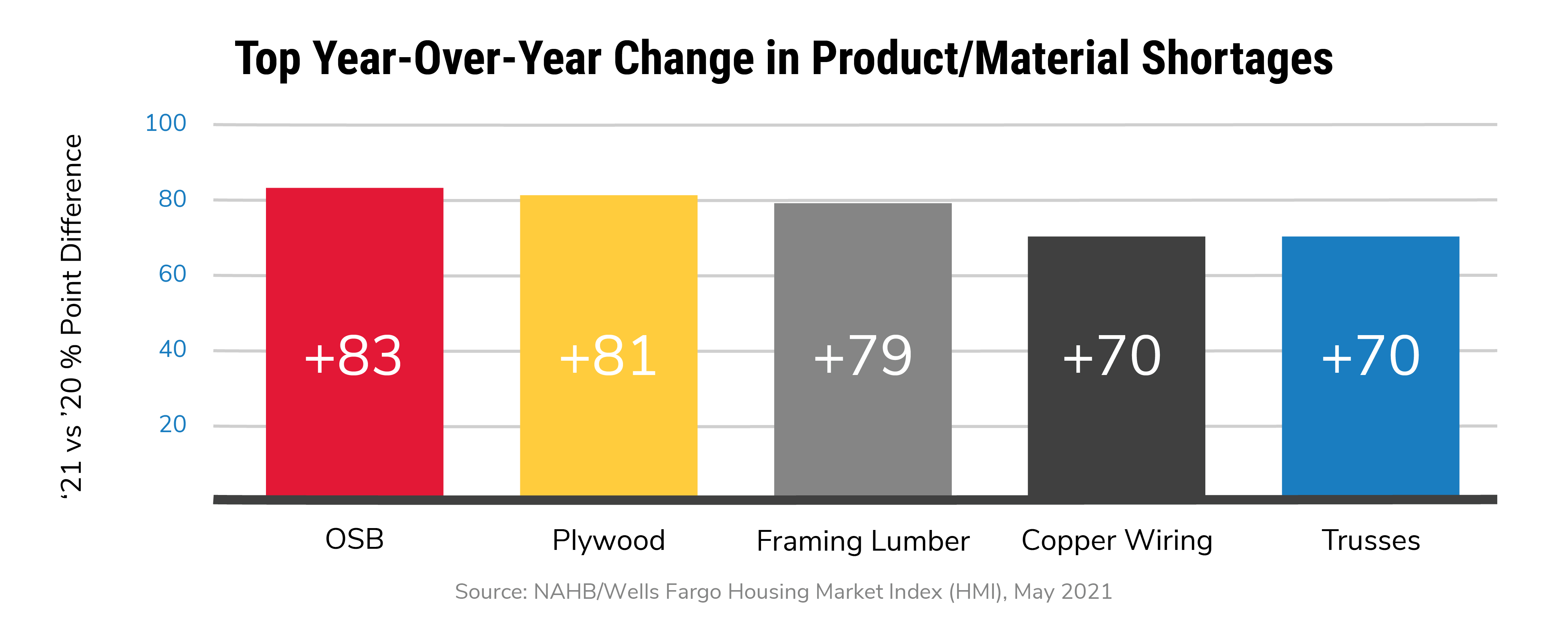

Most of the serious shortages reported by builders currently center around the need for lumber with OSB, plywood, and framing.

The largest year-over-year percentage-point increases in shortages as reported by builders shows four of the five top concerns related to lumber materials.

Substitution is an Opportunity

Old habits in the construction industry are hard to break. Builders get comfortable with materials brands they have used for years. It is easier and more efficient for crews to work with familiar brands. Performance, delivery, and price expectations are known.

At the same time, if there was ever a better time for builders and remodeling contractors to consider new materials, it is now. For example, Ox Engineered Products makes a line of insulated sheathing products to enhance thermal performance. Builders are accustomed to using OSB, but with the shortage, Ox is seeing unprecedented demand and is growing its brand as a viable substitute. The current marketplace forces are delivering an opportunity for challenger brands such as Ox.

Transparency, Communication, and Data Analytics

Inventory pressures on building materials manufacturers can quickly strain channel relationships. It is incredibly frustrating for builders and contractors who have consumers more than ready to buy but must manage expectations for circumstances out of their control. This has a chain effect from the builder to their distributor and all the way back to the OEM. It has forced many manufacturers to assess and re-prioritize their best customers while being willing to lose others.

The pressure is everywhere. The best way to manage through it is with open dialogue and transparency. Invite your customers in to view your production operations. Use technology as an asset. Provide them with data and analytics to identify the pressures, and offer solutions. Set up a dashboard for them to follow order processing and delivery so they can set expectations with their customers down the chain.

Invest Marketing in Recruitment

Coming out of the acute phases of the pandemic, a shortage of manufacturing workers was pervasive. Many building materials manufacturers laid off employees in the early stages of COVID and have had a hard time bringing them back, let alone hiring additional employees to meet increased demand. If you haven’t already, it is time to create a stronger connection between marketing and HR and invest marketing dollars in recruitment activities. Your customers will appreciate reallocating dollars once earmarked for growing your business so you can grow your capacity and better deliver to them what they seek.

Patience and Resiliency

An unpredictable global pandemic has splintered the economic equation for everyone – from suppliers and manufacturers to business owners and homeowners. The strain on supplies and a tight labor market remain persistent. For building materials manufacturers, navigating these waters takes a resourceful and patient approach.

Secure current clients by being connected, engaged, and solutions-oriented.

Drive your differentiation, and chances are you will score new business by seizing on opportunity.

Let’s talk.

Have a specific marketing challenge? Looking for a new agency?

We’d love to hear from you.